What is Fiber Glass ?

Fiber glass is a reinforced composite plastic material which comprises of a woven material that is embedded with glass fibers which are randomly laid across each other and held together with a binding substance. Fiber glass is combined with a hardener resin to form an extremely strong and durable composite.

When could you use fiber-glass?

Following are some of the uses of Fiber Glass:- Custom Sub boxes

- Custom door pods and speaker pods

- Custom dashboard and gauge pods

- Custom body kits

- Body kit repair

- Advantages of Fiber Glass

- Fiber glass allows greater flexibility and design

- Fiber glass allows better use of tight and unusually shaped areas

- Fiber glass is lighter

- Fiber glass is relatively cheap

- Fiber glass is very strong

Disadvantages of Fiber Glass

It can be daunting for a first timer.Dont be Afraid:

Fiberglass can be a bit daunting for a beginner, but its very easy to get the hang of. The more you practice the more you will improve. Most of what I have learnt is through experience. Dont aim too high for your first go and try and make a full custom boot. I recommend starting with a tyre well sub box. The design is simple, theres no tricky angles, and it doesn’t matter if your fibreglass is messy because no one will see it.

Do be Afraid:

Ok, not trying to scare people off but there is a serious side to fiberglass. The materials are flammable and I don’t even want to think about how painful it would be if you got the stuff in your eyes. So always wear protection. Use googles, not safety glasses. Ones that actually seal around your face and a mask.

Fiber Glass Purchasing Guide 2021

The main ingredients are fiberglass matting, resin and catalyst. These can be purchased in kits from most hardware stores however its is very expensive. It is much cheaper to purchase your materials from a fiberglass supplier. Most will sell directly to the public and everyone I have ever dealt with are always friendly and helpful to beginners.

The largest kit that hardware stores usually sell is 1 sq meter. To build an average box for 2 12” subs you are going to use 3 sq meters. And that is with a flat wooden top. If you want a full fiberglass boot installation it is going to cost you a pretty penny. Chop strand mat usually sells for around $10 per sq meter. If you tell the supplier how much matting you want they will tell you how much resin and catalyst you will need.

What you will need:

From the fiberglass supplier:Matting:

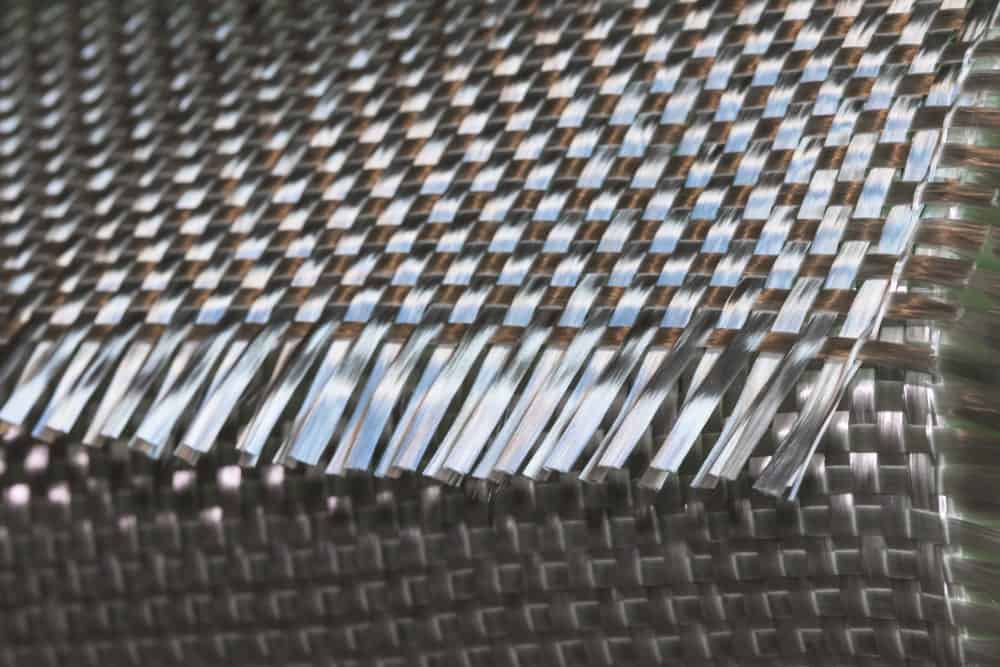

This is available in various types and thicknesses. I use chop strand rather than that woven stuff because its easier to work with. I normally work with 450gm. Its thick enough to provide enough strength after just a couple of layers but not too thick to prevent you from working it into corners. If you need to do some more delicate work with thinner matting you can actually separate the layers (450gm is usually made up of 2 layers).

Resin:

I use a polyester resin. This is the good for stereo work as it bonds well to other layers of fiberglass. It usually comes in 1 kg, 4 kg and 10 kg. 4 kg should be enough for a tire well box. 1 kg if you are just doing some speaker pods and then the big 10 kg tin if you are going all out with a full boot install.

Catalyst:

Ask the supplier which one to use with the type of resin you are purchasing. They will also sell you the correct amount depending on how much resin you have purchased.Measuring Equipment:

You have to be very accurate when you mix the catalyst. There is a variety of devices available to accurately measure out the catalyst such as syringes, test tubes, and eye dropper looking things (cant remember the actual name). I find it very unlikely that you will ever be mixing up enough resin to need anymore than 10 ml of catalyst in one go. In fact you will probably never use more than about 5 ml. So keep that in mind when choosing the correct size.

Acetone:

You will learn to love this stuff. No matter how hard you try you will get resin everywhere! Acetone gets it off. Don't be stingy get yourself a 4 Liter tin, you will use it.Gloves:

I doubt resin does your skin any good and its a bitch to clean, so buy yourself a box of latex gloves.Mixing Sticks:

You can improvise if you want, or you can purchase a box of hundreds of those massive paddle pop sticks that the doctors use for only a few dollars.Roller:

An optional item. Used for getting air bubbles out. Important if strength is crucial but with a sub box a few air bubbles here and there wont make a noticeable difference.Misc. Items you will need :

Containers:

You will need suitable containers to mix up the resin. I have found that margarine/yogurt containers are a good size to work with. Broader is better than tall. The resin will go off quicker in a taller container and give you less time to work with it. The best thing is these containers are free. Most of them can also be reused.

Plastic Drop Sheets:

I use them for two reasons. 1 to protect your car from drips because you will drip resin everywhere and 2 for stopping the glass from sticking to whatever it is you are making. More on that later. You can purchase massive drop sheets from the hardware store (2.5 m x 2.5 m) for the measly sum of $1.50. Bargain!

Paint Brushes:

Used to apply the resin. They don’t need to be expensive, in fact the cheaper the better. The pros clean their brushes each time in acetone, however I have found that its easier and cheaper to get really cheap brushes (under $1.00 each) and just throw them away each time.

Miscellaneous Items:

What you can build with fiberglass is only limited by your imagination, ingenuity and creativity. It doesn’t really matter what you use to make the shapes, even if it has no strength in it. It only has to be strong enough to hold the glass until it dries and then the fiberglass will give your product the strength. This is a list of some of the materials and equipment I use:

- MDF

- Cardboard

- Paper

- Masking Tape

- Lycra

- Wire mesh

- Pens

- Pencils

- Ruler

- Square

- Scissors

- Stanley Knife

- Spirit Level

- Jigsaw

- Airsaw

- Staple Gun

- Nail Gun

Preparing your work space:

- Where possible work in an open ventilated area as the resin does give off strong fumes.

- Work in a well lit area otherwise you will miss areas.

- Work on a level area, you don’t want all the resin to pool in one corner.

- Get everything set up and ready to go before you start mixing resin. Once that resin is mixed you wont have time for anything else other than applying it. Use your drop sheets to cover areas that you aren’t working on. I always cover the route that I need to take with the resin from where im mixing it to where im going to work with it. For example if im working in the boot of a car and I have to carry the resin over the back of the car I will drape a drop sheet over it in case of drips and spills.

- Start by cutting or tearing up the matting. If you want a nice neat edge then cut the matting. However if you want to over lap the matting (this is what you will do most of the time) then tear it. I usually tear up the matting and stack it in piles of different sizes (2 or 3 different sizes will be sufficient).

- When starting out it is difficult to determine how much matting you will need for each layer. I suggest tearing it up and laying out in or on your project to gauge how much you will need. Always prepare more matting than you think you will need. If you run out of matting after you have started applying resin, don’t even bother trying to cut more up as the resin will set before you can cut anymore. Its easier to have left over torn up matting that you didn’t use as it can simply be stored and used again next time.

Mixing the Resin:

Time for eye protection!

Using a ruler and permanent marker I mark a line on the inside of the container im using to the level that I want to fill it to. Its quite easy, if you are using a 500ml container and you want 250ml then just mark it half way. Poor your resin in and replace the lid.

I use a ratio of 1-2% catalyst. 2% will go off very quickly. For beginners, start with 1% until you get the hang of it and can work a little faster. Add the catalyst and mix it thoroughly. You will see it change from blue to a blue/green in under 30 seconds. Start applying. Dab the resin don’t brush it. You want the fibers to soak it up. Brushing will move the fibers and weaken the fiberglass. Apply layers as evenly as possibly and try not to get too many air bubbles.

Hopefully you will apply all of the resin before it sets. However if it starts to set in the container don’t stress just make up another batch. Either make a smaller batch or use less catalyst. With a bit of trial and error you will work out how much resin you can apply in each batch. I suggest starting with 200-300ml and working up from there.

Reusing containers. Dont reuse a container straight away. Any left over resin from the previous batch will mess up your ratios with the new batch. Wait until it’s completely dry and then pull out the hard clump of resin. You should be left with an almost clean container.

Depending on the thickness of your matting, 2-3 layers should be sufficient for a sub box. It shouldn’t have any flex in it if you press hard onto it.

Cleaning Up:

Put all your waste into a plastic bag before putting it in the bin otherwise it will glue itself into the bin. Clean your hands arms elbows and everything else you dipped in the resin with acetone. Sweep up all the loose fiberglass. You don’t want it getting through your house and upholstery.

Tips:

Fiber glassing upside down is very difficult. In fact anything close to 90 degrees is difficult. Depending on the shapes you are making you may need to apply layers in different sections. Wait for one layer to dry then rotate your product and do another later.

Comments

Post a Comment

We love to connect with like minded car enthusiasts. We encourage you to comment and give us your feedback, queries and suggestions.